OMILAB@HS Schmalkalden

The OMiLAB@HS Schmalkalden is dedicated to advancing research on quality management practices in the context of Industry 4.0 and Industry 5.0. Our work addresses the evolving paradigms of Quality 4.0 and Quality 5.0, focusing on how conceptual modeling can be seamlessly integrated with Big Data analytics to enable intelligent, adaptive, and efficient process optimization. Beyond technological innovation, we emphasize ecological sustainability as a core principle, aligning business processes with environmental responsibility and resilience — key aspects of Industry 5.0.

About the OMILAB Node

Today, OMiLAB@HS Schmalkalden extends this vision into the era of Industry 5.0, addressing the paradigms of Quality 4.0 and Quality 5.0. Our research focuses on how conceptual modeling can be integrated with Big Data analytics to optimize process flows and enable adaptive, intelligent quality management. Furthermore, we emphasize the ecological sustainability of business processes, a core principle of Industry 5.0, ensuring that technological innovation aligns with environmental responsibility and resilience.

Competences

- Quality 4.0 / Quality 5.0

- Green Quality Management & Green Lean Six Sigma

- Method Engineering in Industry 4.0 / Industry 5.0

- Enterprise Application Systems

About the Hosting Organisation

The Schmalkalden University of Applied Sciences offers various study programs on a national as well as international level at its five faculties Computer Science, Electrical Engineering, Mechanical Engineering, Business and Economics and Business Law.

The OMiLAB node is located at the Faculty of Computer Science and will be used for teaching and research purposes alike.

Results

Get an overview what this OMiLAB has accomplised! Selected results are presented below as a contribution to the global community:

RUPERT

All further results of the OMiLAB Node are via the organizer.

Activities

The following, selected activities are organized by the OMiLAB.

Study Days 2025 – Exploring Quality 4.0

Participants gained hands-on insights into conceptual modeling and Industry 4.0 approaches, discovering how these methods contribute to process optimization and prepare businesses for the future of quality assurance.

Visit of TEK-UP Delegation at HS Schmalkalden

The visit provided an opportunity to explore digital transformation in manufacturing and business processes, discuss innovative approaches to automation and data-driven decision-making, and strengthen international collaboration in the fields of computer science and engineering.

Collaborative Exchange with TU Ilmenau

Towards Tool-Supported Situational Roadmap Development for Business Process Improvement in the era of Quality 4.0 @NEMO Summer School Series

Resources

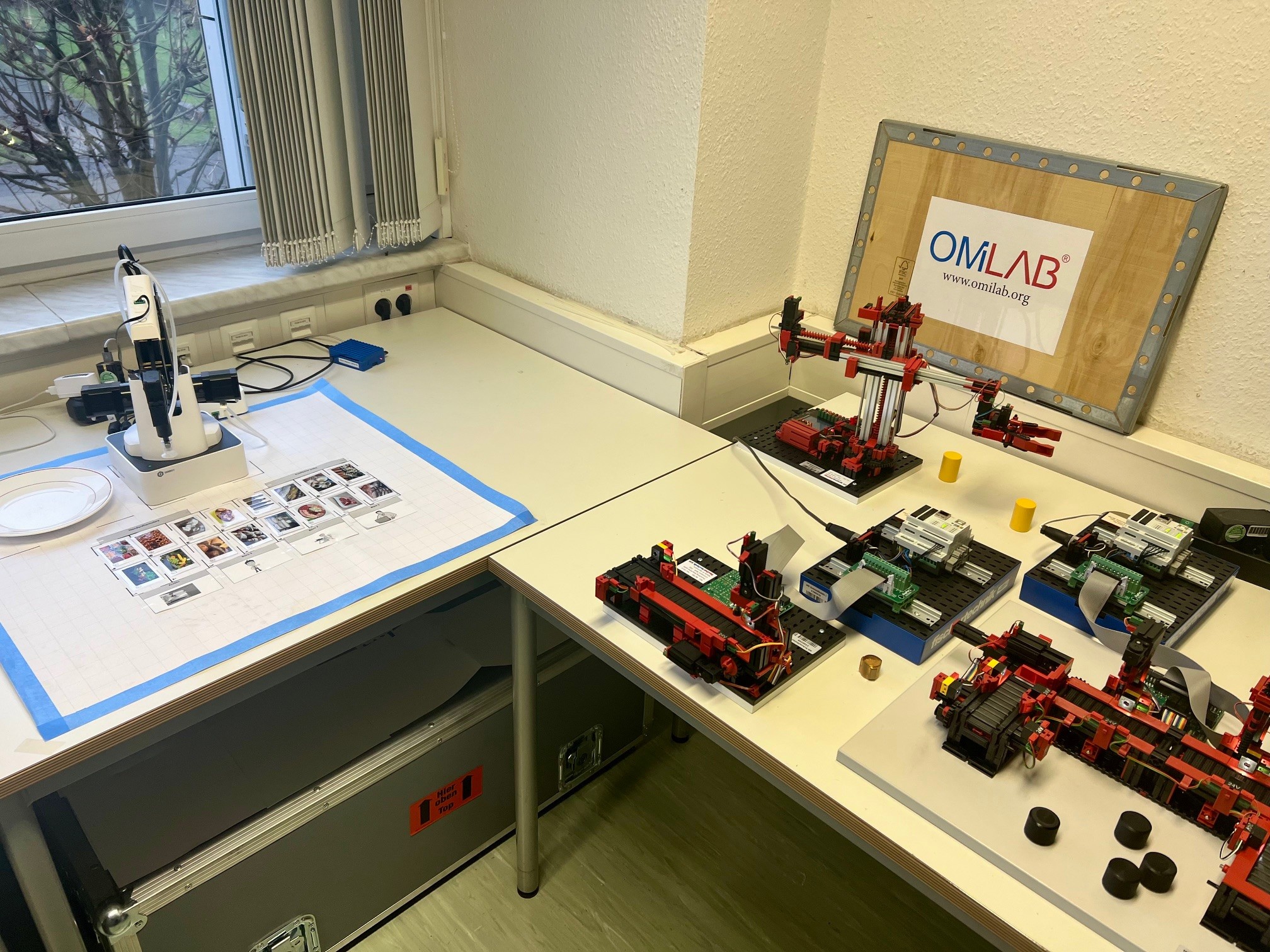

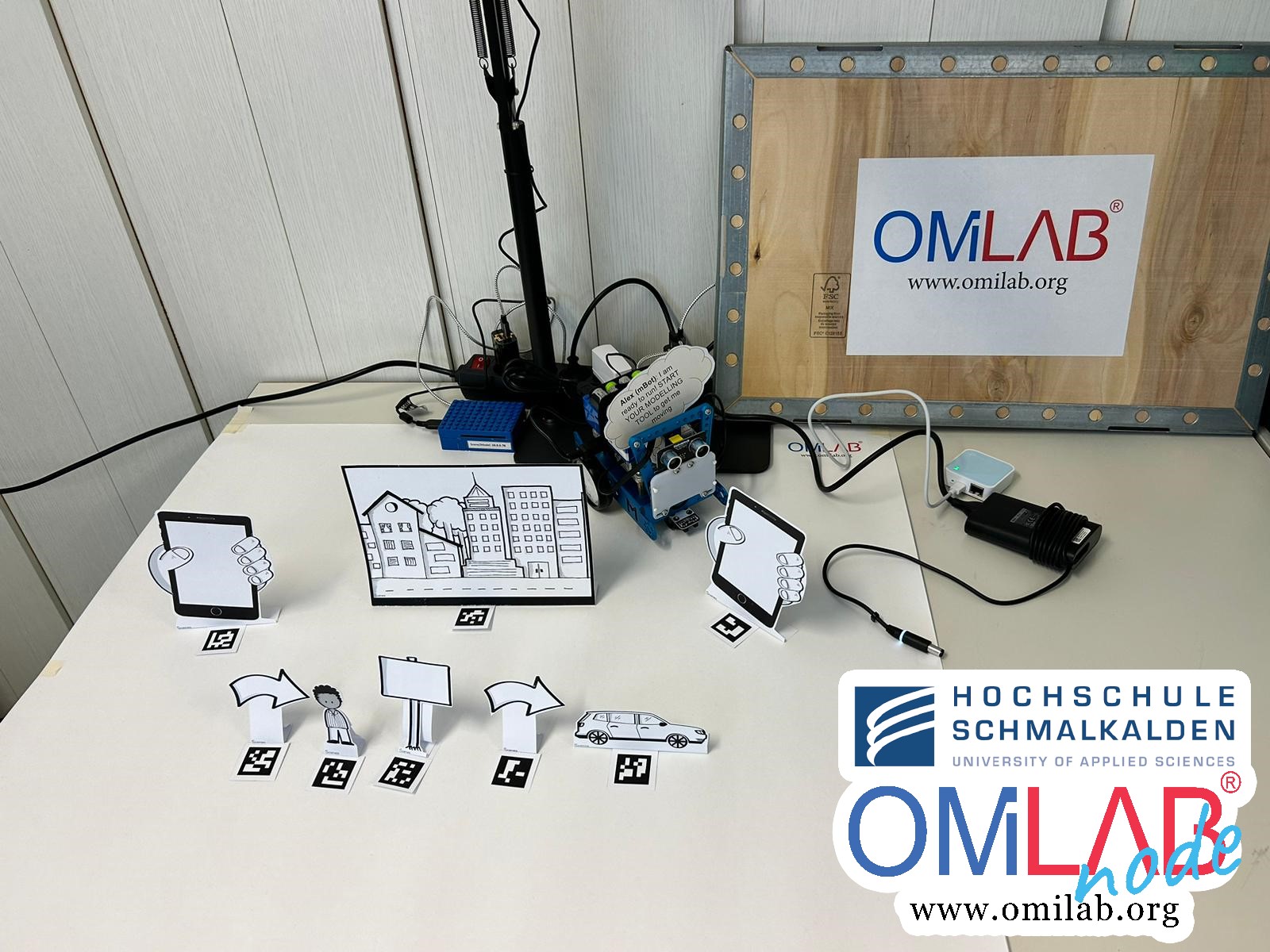

The following cyber-physical resources are available at the OMILAB node:

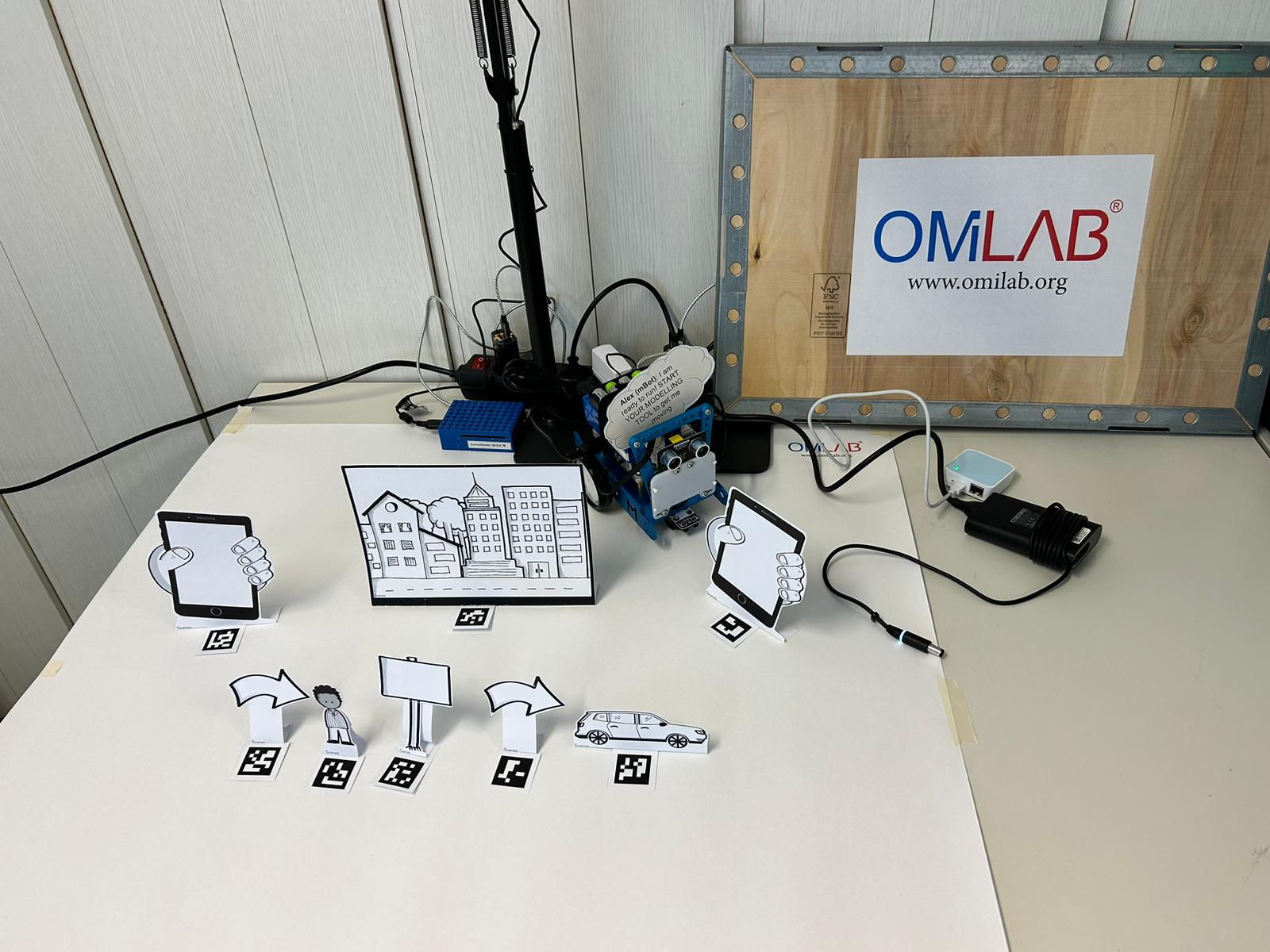

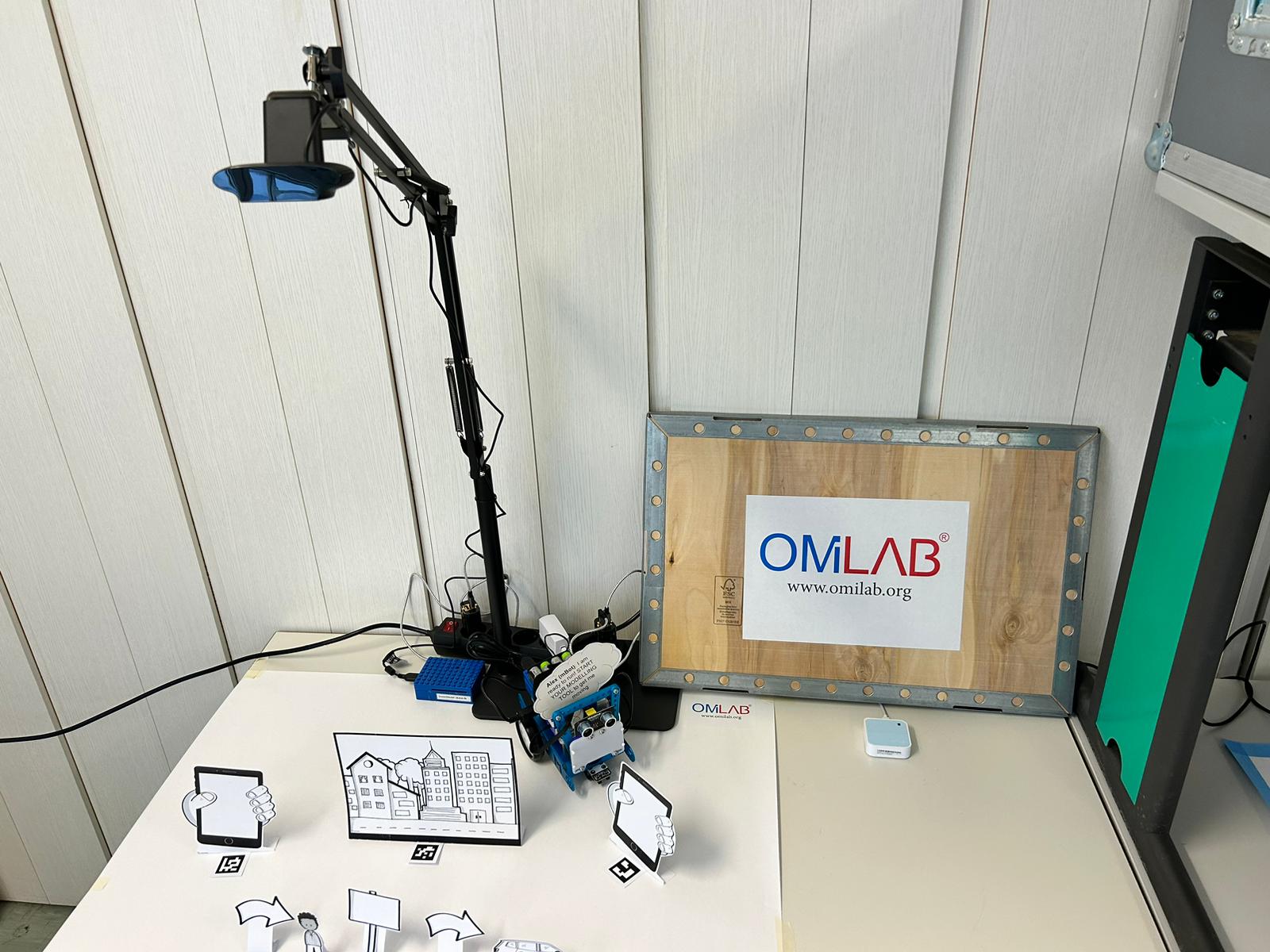

Scene2Model

Business Layer using SAP-Scenes

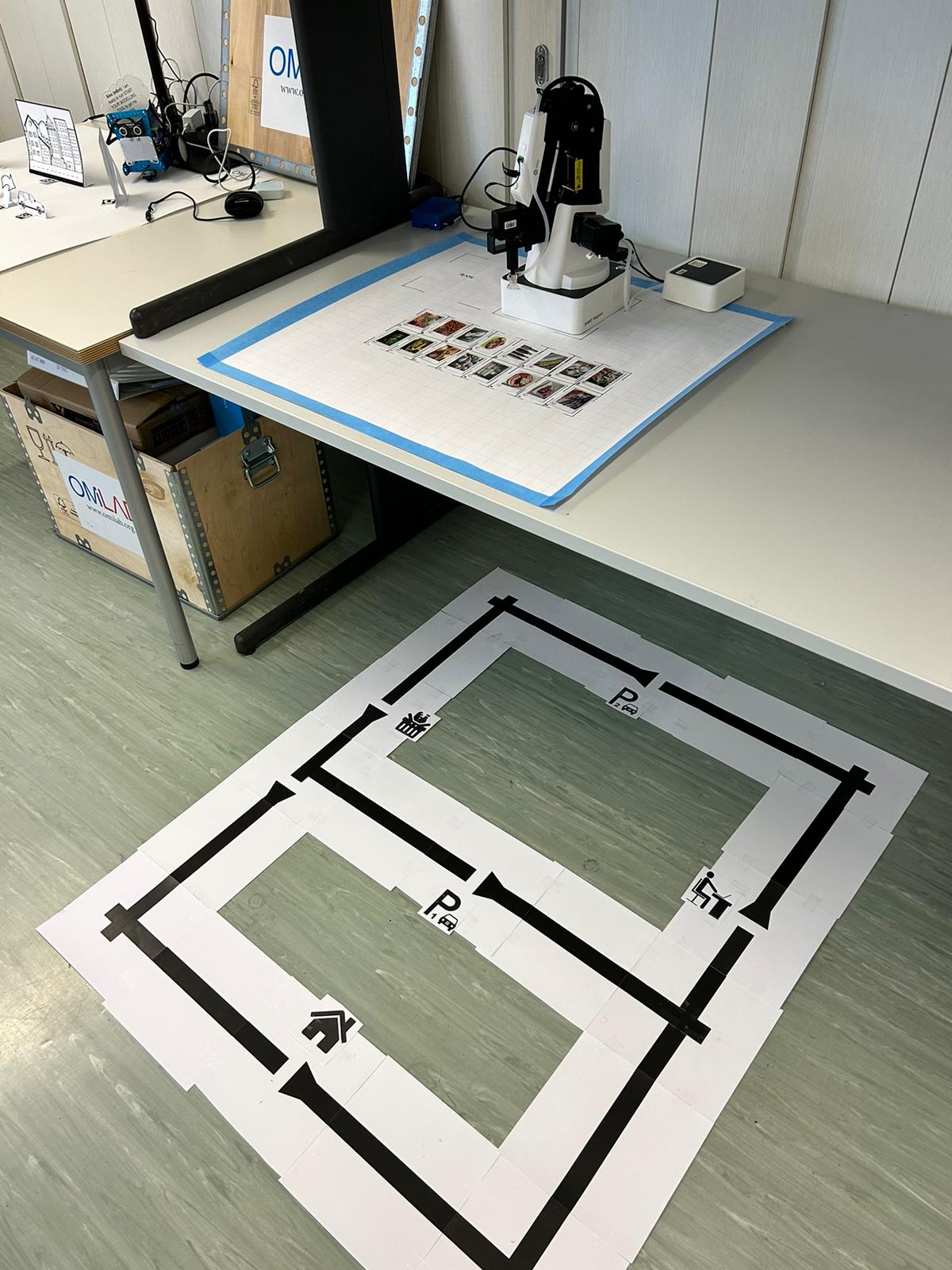

Dobot Magician

Proof of Concept Layer CPS-Device

mBot

Proof of Concept Layer CPS-Device

Fischertechnik Lernfabrik 4.0

9V – Simulation

Further Fischertechnik Components

Fischertechnik – Quality Control with AI (Artificial Intelligence) 9V

Fischertechnik 3-axis robot with gripper Simulation model 24V

Push-pull line with 2 processing stations 24V

Punching machine with conveyor belt 24V

Fischertechnik Robot Construction Kit Robotics Hightech 559895

Programmable logic controller, 24V PLC S7-200 CPU224XP DC/DC/DC PLC Programmable Controller Module

Publications

Relevant publications of the OMILAB node: